One Color Vinyl Cut Out Friends Don't Let Friends Take Home Ugly Boys Vinyl Lettering Sticker. Our Friends Don't Let Friends Take Home Ugly Boys Vinyl Lettering decals are very easy to apply and are designed specifically for outdoor use. Buy your Friends Don't Let Friends Take Home Ugly Boys Vinyl Lettering Sticker from Car Stickers!

Frequently Asked Questions

Counting Picks On A Transfer Sticker

Transfer stickers need to have material manually picked out from enclosed spaces such as letters like "O" and "P". The cutting machine that makes the sticker cuts the material, but does not remove it. A Car Sticker employee will then take a special set of tweezers and remove the material by hand.

What is transfer tape?

Transfer tape, also known as application tape, is a paper or plastic film that can be placed on the top of the sticker or piece of vinyl to make the sticker easier to apply. Transfer tape allows the installer to see exactly where they are placing the sticker on the substrate. Substrate is the term used for the material a sticker is being placed on, such as a window, car door, plastic sign, or anything else you like!

There are many different types of transfer tape, varying from paper, plastic, rolls and sheets. Here at Carstickers we make buying transfer stickers easy by using high quality clear plastic application tape. This works well with cut out stickers that have many different parts because it maintains the positions all of the letters and artwork of your sticker.

Clear tapes are transparent because they’re made from plastic face films instead of paper. The clear plastic construction provides the transparency that is needed for our customers easy placement stickers. With the car windshield, water bottle, laptop or any other substrate surface clearly visible, the installer can clearly see how the sticker will look when placed. Due to the non porous plastic material of the transfer tape, we recommend applying the stickers on a clean and dry surface.

To help you understand why transfer tape is so important to your sticker, here is our step by step process to producing transfer stickers:

STEP 1

After our customers choose one of our premium graphics, upload their own, or creates something new using our custom sticker maker, they select the color and size of the transfer sticker.

STEP 2

Our Graphic Design team then takes the design and prepares it for processing, ensuring that the design will look great for our customers.

STEP 3

Our talented processing team then takes a premium sheet of the selected vinyl color and runs it through a plotter. The plotter is a machine that cuts vinyl to a specified shape or design.

STEP 4

Once we’ve cut out the graphic, our team pulls the excess vinyl away from sticker (called topping) and carefully weeds the excess vinyl with a specialized tool.

Weeding spaces in between letters such as “A” and “O” are called picks.

Too many picks are very time consuming thus require an extra charge.

See our Counting Picks on a Transfer Stage page for more.

STEP 5

When the graphic is topped and weeded, we roll our high quality clear plastic transfer tape over the graphic.

The sticker is then cut to our customers specified dimensions.

Leaving the sticker in a sandwich between the vinyl backing and our transfer tape.

How do I apply the stickers?

We have a comprehensive set of instructions on our Applications Instructions page and a set of these instructions will be mailed with each sticker order.

How long do stickers last?

The life of a sticker depends on the type of sticker material and where its placed. Stickers made out of vinyl and adhesive have a lifespan of up to 5 years while stickers made from cling last up to 6 months. Some specialty materials such as glow in the dark vinyl is not intended for long term outdoor use however it will still last indoors for up to 5 years. Perforated film that creates one-way visibility with its perforated vinyl pattern will last up to 3 years.

For more detailed information on the types of materials we offer check out our stickers materials page.

What Is The Minimum Letter Size You Can Cut As A Transfer Sticker

Best Practices For Uploading A Graphic

Uploading an existing image or design to create a custom sticker is easy! However, there are some common issues with uploaded files that can hold up the production process. Below are a list of best practices for uploaded files that can help you avoid delays in receiving your order.

Embed Images/FilesWhen you place an image or file into your illustrator document, make sure the file is embedded. With the placed file selected, you can see whether the image is Linked or Embedded in the top left corner of the document.

Outline FontsAfter you’ve designed your sticker in Illustrator or other design software, make sure that your fonts are outlined. When artwork is submitted without outlined text, we may not have the fonts needed to print your design as you created it.

White StickersIf you are ordering a sticker where the only color in the design is white, you can choose from a white transfer sticker or a clear vinyl sticker with the design printed in white. Transfer stickers have the design cut out of a piece of white vinyl and then have the background elements removed. Clear vinyl stickers have the design printed in an opaque, white ink and can either be die cut around the shape of your design or cut to a standard shape, such as a circle, square, or oval.

**In some cases, where a transfer sticker is too small to cut, we may recommend changing to a sticker printed on clear vinyl.

Cut Paths On Sticker SheetsWhile ordering a sticker sheet, cut paths are signified by a 1 pt. stroke around your artwork. The stroke must be a spot color with the name “CutContour." For detailed instructions on how to add cut paths to your artwork in Adobe Illustrator, please view this short tutorial video.

If you would like a sticker sheet, but don’t want to worry about setting up your own cut paths, simply select the “I need cut paths” option.

Submitting Transfer Sticker Artwork As A Black ImageWe often receive white artwork on a black background from customers who want to purchase a white transfer sticker. Please submit your artwork as a black image on a white background. Once you upload your file you will be able to select the color of your sticker.

Transfer Sticker File Types| Preferred Files | Not Preferred Files | Do Not Submit |

|---|---|---|

| .EPS | .JPG | MS Office Files |

| .AI | .JPEG | |

| .PSD | ||

| .TIF | .PNG | |

| .CDR |

You can check your file type by looking at the extension at the end of your file name. Example: transfer_sticker_file.eps

Printed Sticker File Types| Preferred Files | Not Preferred Files | Do Not Submit |

|---|---|---|

| .EPS | .TIF | MS Office Files |

| .AI | .CDR | |

| .JPG | ||

| .JPEG | ||

| .PNG | ||

| .PSD |

Are glitter stickers available in a variety of colors?

Yes, glitter stickers can be ordered in white glitter, black glitter, blue glitter, holographic glitter, holographic gold glitter, holographic gunmetal glitter, holographic pink glitter, holographic teal glitter, pink glitter, red glitter, silver glitter, and gold glitter vinyl options.

Are glitter stickers laminated?

No, custom glitter stickers are not laminated.

Raster art vs. Vector art

One way designers get around being stuck with one size is to design in vector art programs (typically Adobe Illustrator and Corel Draw). Vector art programs use paths and shapes instead of pixels (Raster images) to determine shape and color. These shapes and paths can be enlarged and are not dependent to a pixel size, so their quality remains intact when sized. Typically people use vector programs to create logos and text, but are popular amongst designers because of their friendliness towards scalability. Visit our vectorization to find out about getting YOUR artwork vectorized.

Can I get my full color design printed on glitter stickers?

Yes you can get your full color design printed on custom glitter stickers.

How Thick Are Your Stickers?

Our stickers come in a variety of thicknesses based on material type and lamination options. Please see the table below to find the thickness of the sticker material you are looking for. We have included the thickness of the sticker alone as well as when it is still secured to the backing.

Sticker Material Thickness

| Sticker Material | Thickness of Sticker | Thickness of Sticker with Backing |

|---|---|---|

| White Cling | 4.33 mil | 8.27 mil |

| Clear Vinyl | 4.33 mil | 8.27 mil |

| Front-Facing Cling | 4.33 mil | 8.27 mil |

| Reflective Vinyl | 11.8 mil | 17.7 mil |

| Permanent Adhesive | 4.33 mil | 8.66 mil |

| White Vinyl (Most Popular) | 4.33 mil | 8.27 mil |

| Glow in the Dark Vinyl | 13.0 mil | 18.9 mil |

| Front-Facing Adhesive | 4.33 mil | 8.27 mil |

| Perforated Film | 6.7 mil | 12.6 mil |

| Clear Cling | 4.33 mil | 8.27 mil |

Transfer Sticker Guidelines

Each line of text must be at least .25 inches tall. Transfer stickers should be measured by the overall width multiplied by the overall height. Learn more about measuring transfer stickers. Strokes, line weights and art elements should be at least .0625 inches thick. An additional charge may apply if your uploaded artwork has more than 20 picks. Learn more about counting picks. If you would like a proof before your sticker goes into production, you may ask us for one in the special instructions box. Click here to view application instructions for transfer stickers.

What kind of items can custom glitter stickers adhere to?

Glitter stickers can adhere to any smooth surface. They are great for cars, laptops and water bottles! Custom glitter stickers are also popular for adding flair with crafts, invitations, and cards! These stickers are great for indoor or outdoor application.

How Are Stickers Measured and Priced?

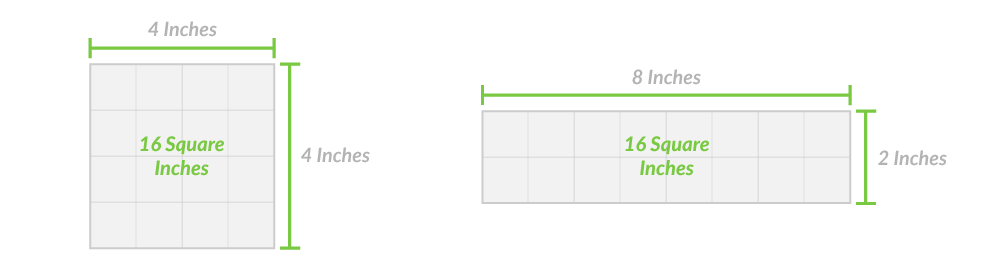

At Carstickers.com, we measure and price all our stickers based on square inches. The easiest way to figure out the square inches of a sticker is to multiply the width by the height. For example, a sticker that is 4”W x 4”H (4 inches wide and 4 inches high), and a sticker that is 2”W x 8”H (2 inches wide and 8 inches high), will cost the same because they are both 16 square inches.

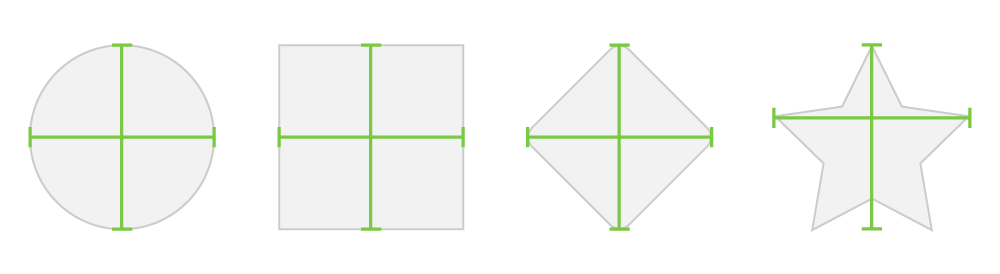

These measurements are based on the widest and tallest areas of the sticker's shape when a straight line is measured from left to right and top to bottom.

Please note: The measurements are taken when the design is upright and in the same position as it will be applied. This ensures the sticker you order will fit in the space intended. In theory, a diamond-shaped sticker could be rotated 45 degrees and measured as a square, but a 3”x3” diamond and a 3”x3” square rotated 45 degrees are not the same size and will not fit in the same space.

What is a Transfer sticker?

A transfer sticker is created by cutting sticker material to a shape, graphic or text, and then removing the background. Transfer stickers are not printed on, but instead are cut from a colored sheet of vinyl. If you would like a sticker with multiple colors but no background you should order a Multi-Color Transfer Sticker.

All of our Transfer Stickers come with three elements. The first is the backing of the vinyl sheet. This is the paper layer that the vinyl is originally cut from. The second layer is the sticker itself, which is cut by our plotters to your exact design. Finally we add a top layer of transfer tape to allow you to place the sticker exactly where you want on your material.

Applying a Transfer Sticker

When you get your transfer sticker in the mail, just lift the sticker and peel the white paper backing off of the adhesive. Then while holding the clear transfer tape, line your transfer sticker with the material underneath and place on the surface. If you have any air bubbles in the sticker, gently rub from the middle to the edges until the sticker lies flat. For more see the Application Instructions Page or watch the video below:

Can I order printed and transfer stickers in glitter?

Yes, glitter stickers can be ordered as transfer stickers as well as printed stickers. You can order your full color design on a printed glitter sticker. You can also order one color transfer stickers and vinyl lettering in glitter vinyl.

Learn more about the various types of glitter stickers below.

About The Friends Don't Let Friends Take Home Ugly Boys Vinyl Lettering S

Create a one color vinyl cut out Friends Don't Let Friends Take Home Ugly Boys Vinyl Lettering Sticker for your car. Our Friends Don't Let Friends Take Home Ugly Boys Vinyl Lettering stickers can be applied to any smooth surface including a car window or the paint of a car. The stickers are outdoor durable and can handle freezing cold temperatures as well as extreme heat. Our stickers are available in 40 + colors and can be customized with text if you choose. Order your sticker from Carstickers.com today.

Transfer Stickers

Transfer Stickers are stickers without a background. Order your transfer stickers from carstickers.com!

View Video Library